Grain Storage Silos

LLC KREATIV-AGROMASH produces silos which are ideally applicable for the storage of grains and oilseeds. Silos are produced using an automated molding installation according to the technology of the German company LIPP-SYSTEM AG using a spiral-folded steel strip (steel) bending into a strong lock.

Lipp technology has proven itself for over 40 years. Spiral folded silos are successfully used in Europe, the USA and Asia. Lipp silos have proven themselves to be robust and reliable structures.

Creative-Agromash owns its own production base, cutting, rolling and bending equipment, which allows all the designs of our silos to be made exclusively at our production in the city of Kremenchug. Silos are manufactured according to the specifications developed by the Institute. Burnt. Our silos have passed all the necessary tests.

The strength and reliability of silos is subject to an expert opinion of the Institute of Steel Construction named. Shimanovsky.

Our company is included in the register of national manufacturers, and silos purchased by agricultural enterprises are subject to partial state compensation of up to 40% of the cost of production.

INSTALLATION TECHNOLOGY

- Automated installation of a silo by a brigade of 4-6 people

- Lack of bolted connections on the silo body

- The integral and tight cover of the case of a silo excludes

destruction and falling of a silo

- Horizontal spiral ribs of cruelty thickness of 10 mm

up to 20 mm located throughout the body

- Vertical stiffeners distribute vertical

load across the silo body

- Smooth surface inside the silo significantly reduces the force

friction of the product against the silo wall, which significantly reduces

vertical load on the body

- Ability to store even wet and liquid products

- Minimum metal content of the silo body

- The term of safe operation is more than 50 years!

- For installation of a silo it is necessary from 2 to 6 installers

(depending on silo size)

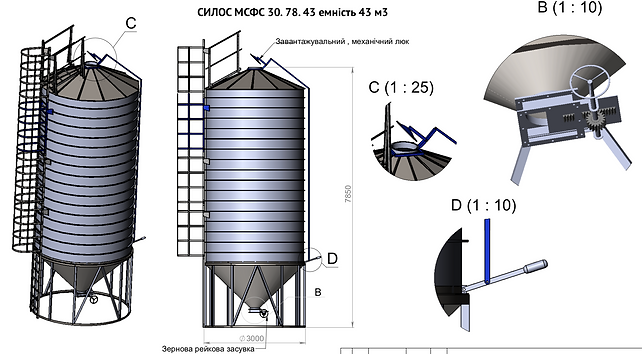

SPECIFICATIONS

The structures of spiral-folded silos (elements of the roof, stiffeners, hatches, stairs, etc.) are made entirely at our enterprise on bending and rolling equipment. The complete installation of the silo is carried out using an automated molding unit at the site at the customer. The roof construction practically does not differ from the roof of traditional panel silos on a bolted assembly.

For the installation of the silo body, we use imported high-quality structural galvanized steel with an electroplated coating of 275 - 450 g / m2. It is possible to use steel with more resistant anti-corrosion properties with German coating Magnelis. The wall thickness of the silo, depending on the diameter and height of the silo, varies from 4.5 mm on the lower tiers to 2 mm on the upper tiers of the silo.

The minimum silo diameter is 4.5 m

Maximum diameter - 32 m

Silo height up to - 30 meters

All silo structures are manufactured and assembled according to

technical conditions and design documentation KM, KMD which was developed by our design office.

In contrast to the manufacturers of panel-bolted silos, which offer their products as temporary collapsible structures with a minimum package of documents with a limited period of responsibility and operation of silos no more than 10 years! We offer silos as facilities that have a life of more than 30 years!

The package includes the following documentation:

- Technical conditions

- Expert opinion of the Institute of Steel Structures

- Executive documentation:

(general, assembly and welding magazines, license for the right to perform installation works, certificates for steel, test reports)

- Silo technical passport

- User's manual

For the history of operation of silos produced by Lipp technology for over 45 years, not a single emergency

Equipment

MSFS silos are completed with the following equipment:

- Inspection inspection hatches (bottom and roofing)

- Wall gates (if necessary)

- Temperature control system with PC controller

- Active ventilation system with fans

- Loading and unloading equipment (conveyor)

- Nadsilosnye transport galleries with supports

- Level sensors (lower and upper)

- Stairs for maintenance of silos

- Sweep radial turning screws

- Fencing on the roof of the silo

- Ultrasonic sensors for the control of products with a GSM controller.

- Technical passport and silo instruction manual

APPOINTMENT OF SILOS

Spiral Folded Silos applicable for storage

the following grains:

- Wheat, barley, oats, buckwheat, canola, meal,

- Sunflower seeds, soybeans, corn, pellets, wood chips, spears

- Flour, sugar, rice and other bulk products.

Technology proven by time! Over 45 years of operation!